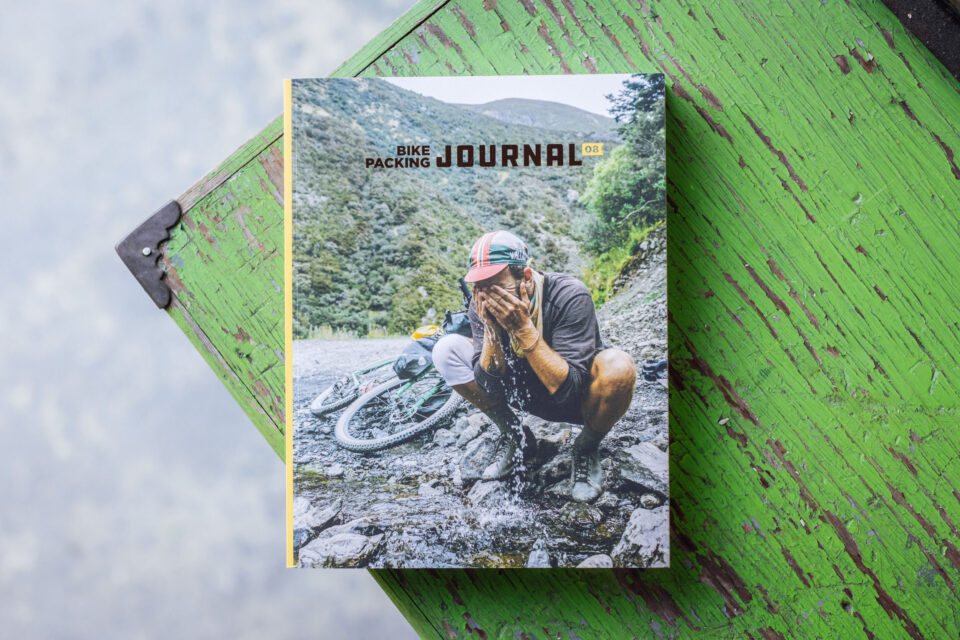

Made in Taiwan

Share This

Made in Taiwan. Made in China. These words have been stigmatized by Western consumers for decades. Cjell Monē recounts his time working with master frame builders there and asks, “Why? Why do we assume ‘Made in China’ or ‘Made in Taiwan’ means shitty?”

Words and photos by Cjell Monē

As I see it, there are two reasons why we think this. One, China has a history of making junk. Two, if you hear it often enough, it becomes a self-fulfilling prophecy. Any anecdotal evidence bolsters your preconceived notion that your Chinese product is of poor quality. That iPhone of yours broke? Oh, made in China.

Despite our group’s strong predisposition to chaos, revelry, and madness, we managed to visit a number of factories. We saw a bit of everything, from high-volume, low-grade aluminum bikes, to carbon fiber, to assembly of completes, to welding steel frames. We got to see old ladies brazing fork crowns, endless rows of welders, racks with hundreds of frames, all of it. This wasn’t just a kid like me making bikes in the back of his bread van. These were real deal bicycle factories, pumping out everything from high-end carbon fiber fat bikes to full-suspension Walmart abominations.

It was an amazing education in the diverse quality found in modern bicycle production. The places we saw ranged from filthy to futuristic and everything in between. It’s a concept that, after so many years of conditioning, people are slowly understanding. Made in China. Expensive, cheap, high quality, low quality. China, in all its manufacturing splendor, is capable of making everything, from low grade to top notch.

The last factory we visited was brazing a number of different frames. Lugged and fillet-brazed road, cross, mountain, and even some cargo bikes. I was watching skilled hand builders prototyping frames using the same techniques and materials as me. That got me thinking. What if, instead of moving into a space outside of my van (my current custom bike factory), I partner with a facility over here that could make exact copies of my bikes?

Fast forward a couple years. Much learning had happened during my first journey from drawing to sample. The particular factory I had started the project with was late in delivery. The quality was hit or miss. There were some alignment issues and clearance didn’t agree with the drawings. Some of the most important design features where botched pretty badly. As far as learning experiences go, this one was as expensive as it was effective.

It was then that I started looking elsewhere. Taiwan was the obvious answer. Taiwan’s quality bike production came up when the US Dollar took a dump in the late 80s and Japanese-made bikes got too expensive. Much of the skill and mastery required to produce high quality bike frames migrated from Japan to Taiwan at that time.

Under the pressure of an increasingly valuable Taiwanese Dollar (bad for exports) and a high worldwide demand for cheap bikes, those clever boys over in Taiwan got together and started sharing secrets. They hatched a plan to let China take over the production of cheaper bikes, while a group of the top Taiwanese bike houses combined their powers to dominate the world of high end bikes. And that’s exactly what they did. If you have a nice bike in your garage and you don’t know where it came from, chances are it was made by someone living 100 miles off the coast of China on an island the size of Maryland.

I couldn’t believe the level of quality and number of bike companies whose parts and frames I recognized being produced in Taiwan. I got to see tubes getting butted in huge hydraulic presses, fork crowns being brazed by 20-headed monster torches, and electrified wires cutting tubes. This was the big league.

All of these guys, from the raw material suppliers to the frame houses to the assemblers, live in the same hood. Taichung and surrounding areas are home to almost all of these companies and factories. Trips to benders, machine shops, and heat treaters are all very convenient in Taichung. Talk about stacking the deck.

After visiting a few factories making chromoly frames and discussing my designs and goals, I got a better picture of what to expect from these people and places. I was able to sit down with every factory owner and discuss details about raw brazing techniques, tube selection, boost spacing, and all sorts of level ten bike nerd stuff. We even discussed the feasibility of making the Monē Changer telescoping chainstays, which either scared or delighted those who I met with.

Everyone I encountered treated me with the utmost respect. The owners of the factories sitting down at conference tables almost made me feel like a fraud—just a dirtbag building bikes out of a van—but we all spoke bike and that made us more similar than different.

I met Lorenzo (a lot of these guys take an English name, which I appreciate when trying to remember it) in his factory south of Taichung. I wasn’t blown away by the appearance of the place. It wasn’t a building of exceptional size. There weren’t hundreds of people working inside. It’s what happened next that captivated me.

Lorenzo, a translator, and I riffed on my bike designs and goals. It was a very in-depth review of gusset placements, seat stay wall thicknesses, and knurling techniques. In the end, I think Lorenzo was impressed with my enthusiasm. I was equally impressed with his extensive knowledge and experience with chromoly frame building.

After poring over bike drawings, we took a look at the bike I brought along and discussed the style of fillets. I’m not sure if he was humoring me, but he seemed impressed and was generally inquisitive about how I’d arrived at the brass-bead style fillets on my frame. He suggested that I sit down and create a brazed joint right then and there. So, he had a guy cut some tubing and we sat down and brazed some tubes together. I remember not being overly excited with my work, but his point was about to be made.

Lorenzo then picked up the torch and proceeded to embarrass me. He worked much faster and with a hotter flame, which wasn’t really a surprise. Anyone with factory brazing experience would be faster than someone without it, but his level of uniformity and ability to make a perfect bead was what amazed me. There are a lot of people who have been fillet brazing for a long time but have never had the need to lay brass down in an obvious and uniform bead, a stack of dimes, as they say.

It’s like he’d been training his whole life for this showdown. I’d just met the Michael Jordan of fillet brazing. We shook hands, and I don’t know if he knew then that he’d be making my bikes, but I did. A couple thousand emails, a decent chunk of my net worth to pay for tooling, and nine months later, things were set to start building bike frames in Taiwan.

I was riding my bike in India when I had the idea of going back to Taiwan to at least watch, and hopefully braze like Mike. The dream was, use the 100 bike frames I had ordered as a way to get a lot more experience with the torch, brazing my own frames. I was already in the area, why not go try to live the dream? Worst case, I’d watch these guys do their thing for a while and then ride my bike around Taiwan.

I watched Lorenzo closely for some time when I first arrived at the factory. I also kept a watchful eye on Young Man. Initially, I was nervous he wasn’t doing as good of a job as Lorenzo. Later, I’d feel silly when it was this kid who was helping me fix the countless mistakes I’d make while brazing. If Lorenzo was Mike, Young Man was Scotty Pippen and Senior Master was Phil Jackson. Does that make me Dennis Rodman?

Those three, along with Dora and Rita, the two hilarious ladies who ran the office and did some odd finish work, were the only people involved with the production of my frames. The entire team, with little to no guidance or communication, autonomously moved from task to task, quietly getting things done. Young Man moved from alignment to brazing while Senior Master tacked front and rear triangles in the fixtures, brazed bosses, and cut bridges. Well oiled doesn’t even come close to describing this machine. Their efficiency and skills were totally braggable.

Lorenzo and I sat side by side and brazed for days on end. His ability to sit on a short stool and work for hours certainly exceeded my own. I adapted, but my back fussed for some time. I imagined I was quite amusing to them, standing and running around the frames I was brazing while Lorenzo sat quietly with little movement as he worked.

We worked brazing front triangles first, then moved onto rear triangles. Lorenzo employed a two-pass strategy to fillet brazing. In his first pass he would quickly lay down a fairly uniform bead, adding extra brass to more acute angles to facilitate a bead of uniform width. He then came back, and formed a perfect fillet by lifting and dropping the flame, almost submerging it in the molten brass puddle. I inquired a great deal as to why he used the two-pass method, and not single-pass like I had been employing. He explained that the second pass was essential to removing any inclusions or imperfections in the bead. His brazing experience and flawless work make a guy tend to believe him. It took me more than a couple days to get the hang of it. I was very humbled by the experience.

The atmosphere at this small factory was on par with its building prowess. Every day, Dora and Rita made lunch for everyone. Every day a bell rang at noon and we all sat around eating a delicious family-style meal and bullshiting (I can only assume, my Taiwanese is slightly worse than my Mandarin, both about zero). They loved offering me chicken feet and even sent me home with a Ziploc full at one point. Pro-tip: there’s nothing magical about chicken feet; they taste and feel like they look, tough and sinewy.

All of this brings me back to the theme here, that Asian production can’t be labeled or generalized in any way. Quality is a result of the unique circumstances that surround every product. In my case, the high quality was a result of the commitment and experience of the people involved. The Chicago Bulls of framebuilding were happy and committed to their craft. Everyone was personally invested in the goals of the factory, and as a result, the products they produced were as good as any I could hope to produce back in Colorado or anywhere.

On the weekends, I was invited along for different hikes and bike rides, very similar to how I’d spend time at home. The Taiwanese are as varied in their interests as anyone I’ve encountered. Their Japanese influence makes for a respectful culture, while their Chinese influence makes them a little more freewheeling. As far as places I’ve visited, Taiwan strikes a great balance between disorder and civility.

I loved it there. I had an amazing and rich experience brazing bike frames alongside the Bulls all stars. After my few trips to China and Taiwan, I’m certainly not qualified to tell anyone how things are done in bike manufacturing, but these two experiences seem to be be indicative of a possible theme. After having worked with two factories on the planet Earth, one in mainland China, and one in Taiwan, I can say I had success at one, and not at the other. Is there any point to making blanket statements? Do the Chicago Bulls of framebuilding know who Steve Kerr is? Are these the best Monē bike frames ever? No, for sure no, and yes, thanks to some serious help from some very skilled island rebels.

Click here to visit Cjell’s website to learn more about the La Roca all-mountain bikepacking hardtail. Also, make sure to read his recent story “Incense and Impasse.”

About Cjell Monē

Cjell is a lifetime bike rider, bike tourist, bike advocate, bike enthusiast, and bike builder. Before starting MONē bikes, which is located in a 1990 Wonderbread Truck, Cjell started his bike building career with Black Sheep Bikes in Ft. Collins, Colorado. Check out his website and follow him on Instagram @monebikes.

Please keep the conversation civil, constructive, and inclusive, or your comment will be removed.